Gaskets may be small components in your vehicle’s engine, but they play a massive role in maintaining performance, efficiency, and safety. In two-wheelers like scooters and motorcycles, gaskets are used to seal engine parts, preventing leaks of oil, coolant, air, and exhaust gases. A damaged or failed gasket can cause serious issues such as loss of compression, overheating, and fluid contamination.

Replacing gaskets frequently isn’t just inconvenient; it can be costly. Fortunately, with the right preventive maintenance practices, you can significantly extend the life of your gaskets and avoid unnecessary repairs.

1. Keep the Engine Cool: Monitor and Maintain Cooling Systems

If your scooter’s engine overheats regularly, the gasket can warp, crack, or blow, resulting in oil leaks or loss of compression.

What You Can Do:

- Regularly check your coolant levels if your scooter uses a liquid-cooled system.

- Replace coolant every 1-2 years or as recommended by the manufacturer to prevent corrosion.

- Maintaining optimal engine temperature not only helps the gasket last longer but also ensures better overall engine health.

2. Choose Premium Engine Oil and Stick to a Regular Change Schedule

Your scooter’s engine oil doesn’t just lubricate moving parts; it also helps cool and clean the engine. Contaminated or low-quality oil can degrade gasket materials, especially rubber or composite gaskets used in the crankcase, valve cover, and oil seals.

What You Can Do:

- Stick to a regular oil change schedule, typically every 2,000–3,000 kilometers for scooters.

- Make sure to change the oil filter every time you perform an oil change.

- Inspect the oil for signs of contamination like discoloration or a milky appearance.

- Fresh, clean oil ensures your gaskets stay soft, sealed, and protected from chemical breakdown.

3. Avoid Over-Tightening Bolts During Repairs

Whether you’re doing your maintenance or relying on a mechanic, gaskets must be installed with the correct torque. Over-tightening bolts can distort metal surfaces or crush the gasket, while under-tightening can lead to leaks and poor sealing.

What You Can Do:

- Always follow the torque specifications in your service manual.

- Use a torque wrench if installing parts like the cylinder head or crankcase cover yourself.

- Ensure surfaces are clean and smooth before installing a new gasket.

- Improper installation is a common but avoidable cause of early gasket failure. A well-installed gasket, on clean surfaces, will seal tightly and last much longer.

4. Watch for Early Warning Signs and Fix Issues Promptly

Gaskets rarely fail without warning. Paying attention to the small signs can help you address issues before they escalate. A minor leak or drop in engine performance might point to a degrading gasket. Ignoring it could turn a simple repair into a major engine problem.

What You Can Do:

- Regularly inspect the engine area for oil or coolant leaks.

- Listen for unusual engine sounds or notice changes in performance.

- Check for white smoke from the exhaust, which may indicate head gasket failure.

- Don’t ignore low fluid levels, especially if they drop quickly without visible leaks.

- Addressing small gasket issues early keeps the rest of the engine protected and reduces long-term maintenance costs.

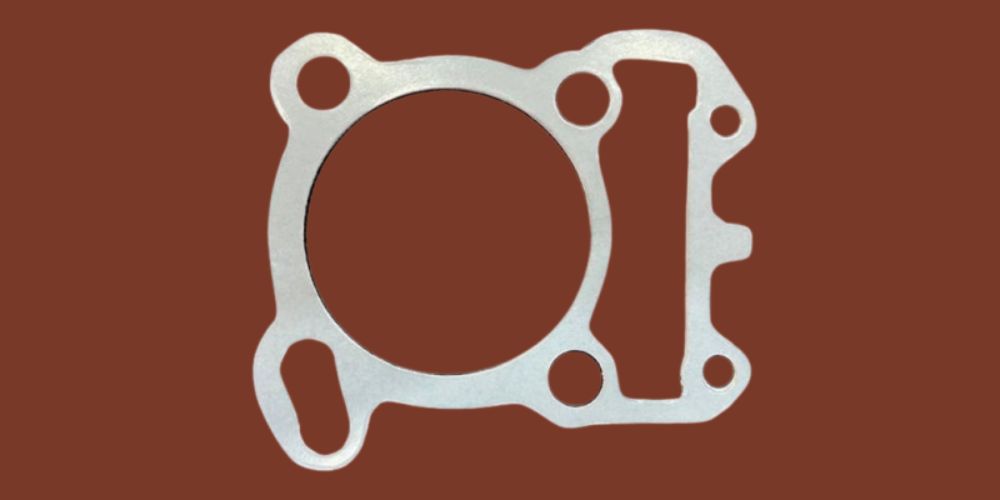

5. Choose High-Quality Replacement Gaskets

Not all gaskets are created equal. When it’s time to replace a gasket, using a cheap or poorly made one can lead to early failure, even if you’ve installed it correctly and maintained the engine well. High-quality gaskets are made from better materials, fit more precisely, and can handle heat and pressure more effectively.

What You Can Do:

- Stick with OEM gaskets or trusted aftermarket brands.

- Avoid generic, low-cost gaskets with poor fit and material quality.

- Look for gaskets that are engine-specific rather than universal.

- Consult your mechanic or do some research before making a purchase.

- A high-quality gasket might cost a little more up front, but it will last longer and protect your engine more reliably.

Bonus Tip: Schedule Regular Tune-Ups

Routine professional tune-ups can identify small gasket or sealing problems early, before they become serious. A mechanic can spot wear, cracks, or loose fasteners that might go unnoticed otherwise. Make it a habit to get your scooter inspected every few thousand kilometers or at least once a year.

Why Celofin Gaskets Are a Smarter Choice

When it comes to replacing gaskets, Celofin Gaskets offer unbeatable quality, precision, and reliability. Manufactured using advanced materials that resist high temperatures, pressure, and chemical exposure, Celofin products are trusted by professionals across the automotive and two-wheeler industries.

Each Celofin gasket is engineered to match or exceed OEM standards, ensuring a perfect fit and long-lasting seal. Whether you’re sealing a cylinder head, crankcase, or exhaust manifold, Celofin provides consistent performance and peace of mind. For riders who want durability without compromise, Celofin Gaskets are a dependable investment in your scooter’s long-term health.

Don’t Miss: Top 5 Signs Your Scooter Needs a New Gasket

Conclusion

Your scooter’s gaskets work silently behind the scenes, but their failure can bring everything to a halt. By monitoring engine temperature, using quality oil, installing parts properly, catching early symptoms, and choosing high-grade replacements, you can extend the life of your gaskets and enjoy a smoother, more reliable ride. Preventive care is the key—protect your engine before problems start.